How Artificial Intelligence is Revolutionizing the Manufacturing Space – Use Cases and Examples

The impact of AI in manufacturing is huge. AI is changing how products are made, making the process more efficient, accurate, and innovative. It is being used to automate repetitive tasks like assembly and packaging and optimize complex processes such as managing supply chains and predicting maintenance needs. AI is helping manufacturers save money, improve product quality, and be more productive.

One of the top AI use cases in manufacturing is predictive maintenance. AI can analyze data to predict when machines are likely to break down so they can be fixed before they cause problems. Another important use case is quality control, where AI can help identify defects and ensure that products meet high standards. AI is also used in supply chain management to optimize processes and reduce costs. These are just a few examples of how AI is making a big impact in manufacturing.

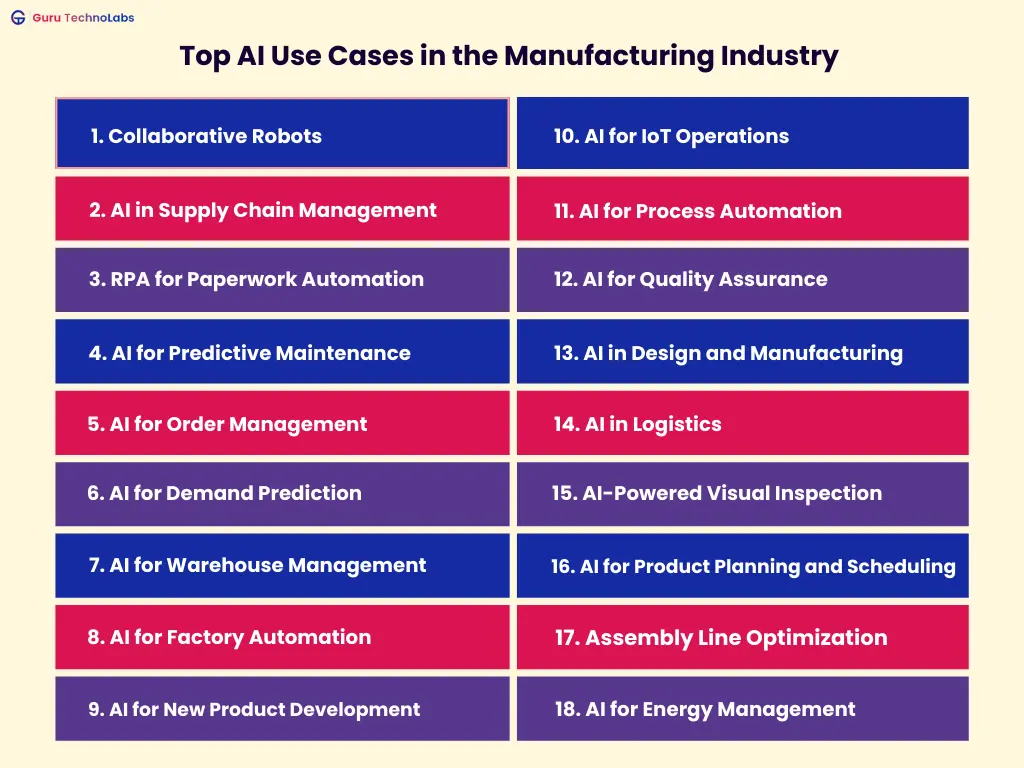

Top AI Use Cases in the Manufacturing Industry

1. Collaborative Robots

Collaborative robots, also called cobots, are made to work alongside human workers in the manufacturing sector. These robots can do tasks like putting things together, welding, and painting accurately and consistently. By doing repetitive and physically demanding jobs, cobots help improve how much gets done and lower the chance of people getting hurt at work.

One great example of cobots at work is Universal Robots. Their cobots are widely used in industries like cars and electronics to make production smoother. For example, Universal Robots’ cobots help put car parts together in the car industry. These cobots work fast and ensure each part is put together the right way every time, speeding up production and keeping the quality high.

Another real-life example is making electronics, where cobots are used for gentle jobs like soldering and placing parts on circuit boards. This type of artificial intelligence used in the manufacturing industry shows how cobots can do very accurate work that might be hard for humans to do perfectly every time without making mistakes.

In short, cobots are a big deal in the manufacturing industry, providing many benefits by making things faster, keeping quality high, and ensuring people stay safe. This is just one of the many examples of artificial intelligence used in manufacturing to show how AI is improving manufacturing.

2. AI in Supply Chain Management

AI has a significant impact on how companies manage their supply chains. It helps them predict how much product to make, figure out the best inventory levels, and spot potential problems before they happen. This technology looks at a ton of data from different places to help companies make smart choices and keep their supply chains running smoothly.

Let us take IBM as an example. They use AI to look at data from suppliers, production lines, and market trends. This is a great use case of artificial intelligence in the manufacturing industry. It helps companies figure out how much product customers will want so they can make just the right amount at the right time. It also helps them keep the right amount of products in stock so they do not waste space or money.

AI can also help spot supply chain issues, like if raw materials are going to be late or if the market is going to change. By predicting these problems, companies can take action to fix them and avoid losing money or time.

We can see AI in action when we look at Walmart. They use AI to guess how much each product their stores need. Looking at past sales, weather, and local events, AI helps Walmart ensure its stores have the right products in stock at the right time. This is a great example of AI in the manufacturing industry.

Overall, using AI in manufacturing has many benefits. It helps companies save money and work better. These examples of AI in manufacturing clearly show how AI can make traditional supply chains work faster and wiser.

3. RPA for Paperwork Automation

Robotic Process Automation (RPA) is changing the game by automating administrative tasks such as data entry, order processing, and invoicing. RPA allows manufacturers to reduce errors, speed up processes, and free employees to focus on more strategic and creative tasks.

Companies like UiPath provide RPA solutions widely used in the manufacturing industry. These solutions help automate repetitive and time-consuming paperwork, making operations more efficient.

For instance, RPA can handle order processing in the automotive manufacturing industry. Instead of manually inputting order details, RPA can accurately and swiftly capture and input this data. This saves time and reduces the risk of errors that can occur with manual entry.

In the electronics manufacturing industry, RPA is used to manage invoicing. The RPA software can generate and send customer invoices, track payments, and update the accounting system automatically. This ensures a smooth and accurate invoicing process, allowing the finance team to concentrate on crucial financial analysis and planning tasks.

This real-life example demonstrates the use case of artificial intelligence in the manufacturing industry, showing how RPA can streamline administrative functions and enhance overall productivity. Integrating RPA allows manufacturers to efficiently handle large volumes of paperwork accurately, which is crucial in today’s fast-paced manufacturing environment.

RPA is among the key AI use cases in manufacturing, offering significant benefits by automating routine tasks, reducing errors, and freeing up human resources for more strategic roles. This illustrates how AI in the manufacturing industry can revolutionize traditional administrative processes, ultimately improving operational efficiency and productivity.

4. AI for Predictive Maintenance

Predictive maintenance is one of the valuable uses of artificial intelligence in the manufacturing industry. It helps predict when machines might break down before it happens. This is done by using AI to study data from sensors and other sources on the machines. The AI looks for patterns and irregularities in the data that could signal potential problems.

This proactive approach is much better than waiting for machines to stop working suddenly. By catching issues early, companies can avoid unexpected and expensive downtimes and make their machines last longer. Production can run more smoothly, and businesses can save money on repairs and avoid losing productivity.

An example of AI in manufacturing is General Electric’s Predix platform. Predix uses AI to study data from sensors installed on industrial equipment. For example, Predix can keep an eye on critical machines like turbines or compressors in a manufacturing plant. Suppose the AI notices any strange vibrations or temperature changes. In that case, it can alert maintenance teams to check the equipment before a breakdown occurs. This helps the plant avoid sudden stops in production, which could be expensive and disruptive.

Predictive maintenance is an excellent example of an AI use case in manufacturing with significant benefits. By using AI to predict and address potential machine problems, manufacturers can improve reliability, reduce maintenance costs, and keep their operations running smoothly. This shows how AI in the manufacturing industry can boost efficiency and prevent costly downtime.

5. AI for Order Management

AI is making a big difference in how manufacturing companies handle their orders. It uses technology to process orders, track them, and ensure they are delivered on time. This helps companies make their customers happier and run more smoothly.

One way AI helps is by taking care of the whole order process. For example, it can automatically process orders by reading and entering details, keeping an eye on each order, and managing inventory. This means less need for people to step in and fewer mistakes. An excellent example of how AI is used for order management is Amazon. They use really smart AI systems to keep track of everything they have and ensure orders get sent out quickly.

When you order something from Amazon, AI helps you determine which warehouse to ship from, track your order, and estimate when it will reach you. This makes getting your stuff faster and ensuring it arrives on time.

AI can be used in the same way in manufacturing. For example, an electronics company might use AI to handle orders for different parts. The AI system could monitor how many parts they have, predict when they need more, and order them automatically. This ensures they never run out and their production keeps going smoothly.

AI for order management is a big deal in manufacturing. It makes processing and tracking orders easier, makes things run more smoothly, and makes customers happier. By using AI for these tasks, companies can handle orders better and keep things running smoothly. These are just a few examples of how AI is improving traditional manufacturing order management processes.

Streamline Your Order Management with AI

Ready to transform your order management process with AI? Contact us today to

optimize your operations and enhance customer satisfaction.

6. AI for Demand Prediction

Predicting how much stuff people want to buy is essential for factories because they need to know how much to make. If they make too much, they will have lots of extra stuff lying around, but if they do not, they will not have enough for people to buy. That is where AI comes in. It can look at how much stuff people bought before and what is happening in the world and then figure out how much stuff people will want.

For example, a company called Blue Yonder uses AI to help factories figure out how many clothes people will want to buy. They look at past sales and what is cool right now, and then they can make just the right clothes. Another example is a company that makes electronics, and they use AI to plan how much to make by looking at past sales and what new electronics are coming out.

This AI stuff is one of the best things for factories these days. It helps them not make too much or too little stuff, so they can save money and ensure they have enough for people to buy. It is a super helpful tool for factories to plan and prepare for what people want. AI in manufacturing is an excellent example of how technology can help make things better and more efficient.

7. AI for Warehouse Management

AI is revolutionizing warehouse management, transforming how inventory is tracked, items are picked, and space is utilized. This technology is one of the top AI use cases in manufacturing. It is crucial for improving efficiency and cost-effectiveness in warehouse operations.

AI enables warehouses to enhance inventory management by tracking stock levels in real-time. Using AI algorithms to analyze data, warehouses can predict inventory needs, preventing overstocking and stockouts of popular items. This ensures that the right amount of stock is always available, which is essential for smooth operations.

Another top AI use case in manufacturing is AI optimizing the picking process. AI-powered robots and drones can retrieve items from shelves quickly and accurately, reducing order processing time. These robots navigate the warehouse autonomously, improving the picking process and cutting down on labor costs while enhancing order accuracy.

For example, Amazon’s fulfillment centers exemplify AI in manufacturing for warehouse management. By combining AI and robotics, Amazon efficiently handles its massive inventory. AI systems manage inventory levels and direct robots to suitable locations, speeding up order fulfillment and maintaining high accuracy.

In another illustration of AI in manufacturing, a large food manufacturer uses AI to track perishable goods, ensuring proper stock rotation and minimizing waste. Additionally, AI-driven robots efficiently pick and pack items, aiding the manufacturer in meeting order demand and improving overall productivity.

AI for warehouse management represents a leading AI use case in manufacturing by enhancing inventory management, streamlining picking processes, and utilizing warehouse space more effectively. These examples of AI in manufacturing demonstrate how AI revolutionizes traditional warehouse operations, making them faster, more precise, and more cost-effective.

8. AI for Factory Automation

AI is revolutionizing warehouse management, transforming how inventory is tracked, items are picked, and space is utilized. This technology is one of the top AI use cases in manufacturing. It is crucial for improving efficiency and cost-effectiveness in warehouse operations.

AI enables warehouses to enhance inventory management by tracking stock levels in real-time. Using AI algorithms to analyze data, warehouses can predict inventory needs, preventing overstocking and stockouts of popular items. This ensures that the right amount of stock is always available, which is essential for smooth operations.

Another top AI use case in manufacturing is AI optimizing the picking process. AI-powered robots and drones can retrieve items from shelves quickly and accurately, reducing order processing time. These robots navigate the warehouse autonomously, improving the picking process and cutting down on labor costs while enhancing order accuracy.

For example, Amazon’s fulfillment centers exemplify AI in manufacturing for warehouse management. By combining AI and robotics, Amazon efficiently handles its massive inventory. AI systems manage inventory levels and direct robots to suitable locations, speeding up order fulfillment and maintaining high accuracy.

In another illustration of AI in manufacturing, a large food manufacturer uses AI to track perishable goods, ensuring proper stock rotation and minimizing waste. Additionally, AI-driven robots efficiently pick and pack items, aiding the manufacturer in meeting order demand and improving overall productivity.

AI for warehouse management represents a leading AI use case in manufacturing by enhancing inventory management, streamlining picking processes, and utilizing warehouse space more effectively. These examples of AI in manufacturing demonstrate how AI revolutionizes traditional warehouse operations, making them faster, more precise, and more cost-effective.

9. AI for New Product Development

AI is changing the way new products are made in the manufacturing industry. It helps companies understand what people want and what is popular in the market. By using AI, businesses can make products that people will like and do well in stores.

An excellent example of this is Nike. They use AI to make better sportswear and shoes. With AI, they can look at what customers like, keep up with fashion, and see how well their products are doing. This lets them make changes to their products quickly so that they stay popular.

Another example is in the car industry. AI can help companies make new car models that are safe and that people want to buy. Using AI, they can learn about how people drive, what safety features are essential, and what people like in a car. This helps them make cars that people will want to buy.

Using AI in manufacturing to make new products is a great way to compete with other companies. AI helps companies understand what people like so they can make new and popular products. These examples show how AI can help the manufacturing industry make products that people want and be more successful.

10. AI for IoT Operations

Manufacturers are using AI to improve their operations. They connect their machines to the internet, which helps them gather information. Then, AI looks at this data and determines ways to do things more efficiently. For instance, Honeywell uses AI and IoT to monitor their machines.

They collect data from sensors all over their factories and use AI to analyze it. If something seems off, AI can either fix it on its own or tell someone about it. This keeps everything running smoothly and avoids any unexpected issues.

Another example is when factories use IoT sensors to monitor their machines. These sensors watch things like temperature and vibration. AI can then use this information to predict when a machine might need some attention. This way, they can fix things before they break and keep the factory running smoothly.

Using AI in manufacturing makes a big difference. It helps factories run better, make better products, and avoid unexpected stops. These examples show how powerful AI is in manufacturing.

Boost Your Manufacturing Efficiency with AI

Ready to enhance your IoT operations with AI technology? Contact us today to

optimize your processes and keep your factory running smoothly.

11. AI for Process Automation

Using AI in manufacturing is changing how manufacturing processes are handled to make them more efficient and cost-effective.

In simple terms, using AI in manufacturing means using innovative technology to look at information from different parts of the manufacturing process to find areas that could be improved. For example, ABB is a top company that uses AI in its manufacturing process to find and fix problems in the production line. This helps the company to keep things running smoothly and save money.

Another example is a beverage company that uses AI to monitor its production process. If something goes wrong, the AI tells the operators what to do so the company can keep making good quality products.

AI use cases in manufacturing prove that AI can make production better and cheaper. It helps companies make their products faster and save money to stay ahead in their industry.

12. AI for Quality Assurance

AI is changing the way we check products for flaws in manufacturing. It uses innovative technology to find defects and ensure products are good. It does this by looking at pictures and sensor data to find problems people might miss. This helps make sure products are better, and there are fewer mistakes when making them.

In simple words, AI for checking product quality means using advanced tech to find problems with products. The AI can be taught to see even the most minor issues by looking at pictures of products or data from sensors. This helps companies find problems early and keep the quality the same.

For example, Landing AI makes AI-powered systems that check products as they are being made. These systems use innovative tech to look at pictures of products when they are being made. If the AI sees a problem, it tells the workers immediately so they can fix it. This means fewer harmful products get sent to customers, and the products stay outstanding.

Another real-life example is in the electronics world, where AI is used to check circuit boards. The AI looks at pictures of the boards to find tiny problems that might make the boards not work well. By finding these problems early, companies can be sure their products are good and do not need to be sent back.

AI for checking product quality matters a lot in manufacturing. It uses smart tech to find problems and ensure products are excellent. These examples of AI in manufacturing show how AI tech can improve product quality checks. By using AI tech in manufacturing, companies can improve product quality checks and provide excellent products to their customers.

13. AI in Design and Manufacturing

AI is changing the way things are designed and made. It helps by creating new designs and making production methods better. This technology lets manufacturers try out different designs and pick the best ones.

One big way AI helps with designs is through something called generative AI. This AI can make many design options based on materials, weight, and strength. This lets manufacturers look at different choices and pick the most efficient and practical design. For example, Autodesk’s generative design software is used in the manufacturing industry to make complex and efficient designs that would be tough for human designers to think of.

AI also helps with how things are made. It can study how things are made and suggest ways to improve them, making things more efficient and costing less. For example, AI can decide the best way to arrange parts in a 3D printer using less material and time to make things.

A real-life example of AI in manufacturing is the car-making business. Car makers use AI to make parts that are light but strong. AI helps engineers make solid and safe parts but also costs less.

In another case, a company that makes electronics for regular people might use AI to design and make circuit boards. AI can make many different layouts for the circuits and make sure they are made to save space, get rid of heat, and keep the signals inside good. This ensures that the thing you make works well and is easy.

AI in manufacturing is one of the essential ways AI is used in making things. It uses intelligent math rules to make new designs and better ways to make things, which gives us better things to use and cheaper ways to make them. These examples of AI in manufacturing show how AI is changing these industries and improving how they are made and designed.

14. AI in Logistics

The use of AI in manufacturing is making a big difference in how things get from one place to another. By using innovative technology, companies can figure out the best way for delivery trucks to go, considering things like traffic and road closures. This not only speeds up deliveries but also saves fuel and money.

AI is also helping companies keep track of their products more innovatively. By looking at what people are buying and trends in the market, AI can predict what will be in demand and ensure there is enough in stock. This helps keep everything running smoothly and prevents having too much or too little stock.

DHL is a real-life example of using AI in logistics. They use it to make their deliveries more efficient and determine the best routes based on GPS and weather. This helps them ensure things get delivered on time, even when things are tough.

In the retail world, companies also use AI to manage their supply chains. AI keeps an eye on how much each product there is and orders more when running low. This helps ensure that products are always available when people want to buy them, making customers happy and boosting sales.

These are just a few examples of how AI is used in manufacturing. AI makes deliveries and inventory management smarter, making things run better for companies and their customers.

15. AI-Powered Visual Inspection

The use of AI in manufacturing has significantly improved quality control. AI-powered visual inspection systems have been a game-changer in the manufacturing industry. These systems use advanced technology like computer vision and machine learning to quickly and accurately identify product defects and irregularities.

In simple terms, AI-powered visual inspection involves using cameras and sensors to take detailed images of products as they move through the production line. AI algorithms then analyze these images to spot any issues. This process ensures that only top-quality products reach the market, reducing the chances of customer complaints and returns.

One of the main advantages of AI-powered visual inspection is its ability to work continuously without breaks, maintaining consistent inspection quality throughout the production process. This ultimately leads to higher efficiency and lower costs for manufacturers.

A real-life example of using AI in manufacturing for visual inspection is Cognex, which offers AI-driven visual inspection solutions for various manufacturing applications. For instance, Cognex systems can inspect circuit boards in the electronics industry to ensure all components are placed and soldered correctly. Any defects or irregularities are immediately flagged for correction, ensuring the final product meets high-quality standards.

Another example is the automotive industry, where AI-powered visual inspection systems check car parts for defects. These systems can accurately detect even the most minor imperfections, such as tiny cracks or surface blemishes; human inspectors might miss that. This helps manufacturers maintain high-quality standards and ensure the safety and reliability of their vehicles.

These AI use cases in manufacturing demonstrate how AI can significantly improve efficiency, reduce costs, and ensure high-quality products.

16. AI for Product Planning and Scheduling

The use of AI in manufacturing is a game-changer, especially in product planning and scheduling. AI analyzes information like production data, demand predictions, and resource availability to ensure everything runs smoothly and products are delivered on time.

In a nutshell, AI helps manufacturers plan and schedule their production better. It uses past production data and current market demand to predict how much of a product will be needed and when. AI also considers raw materials, machinery, and labor availability to create the best production schedule. This way, manufacturers can avoid delays and maximize their resources. There is a real-life example of AI use cases in manufacturing in SAP’s AI-driven solutions. SAP uses AI to help manufacturers make their operations more efficient.

For instance, in a factory making consumer electronics, SAP’s AI can analyze sales trends and inventory levels to forecast demand accurately. It then creates a detailed production schedule to ensure all the necessary materials and labor are available correctly, cutting downtime and increasing efficiency.

Another example can be seen in the automotive industry. Car manufacturers use AI to plan and schedule the production of different models based on current market demand and available resources. AI helps them determine the best order for making different models to increase efficiency and meet delivery deadlines.

The use of AI in manufacturing and its use cases in manufacturing is essential. AI helps manufacturers analyze data and make intelligent production schedules and resource allocation decisions. These AI examples in manufacturing show how AI technology can improve efficiency, cut costs, and ensure products are delivered on time in the manufacturing industry.

17. Assembly Line Optimization

The use of AI in the manufacturing industry is changing the way assembly lines operate. AI analyzes data from the production process to find ways to make the lines run more smoothly. By identifying inefficiencies, AI suggests changes to streamline the workflow, reduce cycle times, and improve productivity.

For example, at Ford, AI systems analyze production line data to detect slowdowns and suggest adjustments to keep everything running smoothly, such as changing the speed of the conveyor belt or rearranging the sequence of tasks. This speeds up production, reduces costs, and improves manufacturing efficiency. In the electronics manufacturing industry, AI is used to optimize the assembly of complex products like smartphones and laptops. It analyzes the assembly process to suggest the best order for assembling components, leading to faster production times and higher-quality products.

Overall, using AI in the manufacturing industry is crucial for making assembly lines more efficient and cost-effective, benefiting both manufacturers and consumers.

18. AI for Energy Management

The use of AI in the manufacturing industry is changing how energy is managed. AI analyzes energy usage patterns in factories and finds ways to save energy. This helps companies reduce costs and support sustainability efforts.

In simple terms, AI helps manufacturers use energy more efficiently. It looks at how much energy is used at different times and in different factory parts. Then, it suggests changes to reduce waste and improve efficiency. Doing this lowers energy bills and helps companies meet their sustainability goals by reducing their carbon footprint.

A real-life example of AI in energy management is Schneider Electric’s EcoStruxure platform. This platform uses AI to monitor and manage energy consumption in manufacturing plants. For instance, EcoStruxure can analyze data from various sensors to determine when and where energy is used inefficiently. It can then recommend adjustments, such as changing the operation times of machines or optimizing lighting and heating systems, to save energy. This leads to significant cost savings and more environmentally friendly operations.

Another example is the automotive manufacturing industry, where AI systems optimize energy use during production. AI can monitor the energy consumption of different machines and processes, identifying opportunities to reduce usage without affecting productivity. This helps manufacturers cut costs and reduce their environmental impact.

AI in the manufacturing industry plays a crucial role in managing energy consumption. By analyzing usage patterns and identifying opportunities for savings, AI helps manufacturers optimize energy use, reduce costs, and support sustainability efforts. These AI use cases in manufacturing demonstrate how AI can make energy management more efficient and environmentally friendly.

Conclusion

The use of AI in the manufacturing industry is a game-changer. AI helps factories become more efficient, cut costs, and ensure high-quality products. It can predict when machines need maintenance and make intelligent decisions to enhance every part of the manufacturing process, leading to smoother operations and better outcomes.

Embracing AI in manufacturing is not just a smart move but necessary for future success. AI technologies will be essential for manufacturers to stay competitive and meet new challenges in the market.

Frequently Asked Questions

Typical AI applications in manufacturing include predictive maintenance, where AI predicts when machines might fail to prevent breakdowns. Quality assurance uses AI to check products for defects, ensuring they meet high standards. Supply chain optimization involves AI analyzing data to improve inventory management and delivery times. Process automation uses AI to streamline tasks, making production more efficient and reducing costs.

Yes, it can. AI improves things, reduces waste, and predicts when machines need fixing. This helps prevent expensive breakdowns. Manufacturers save money and do better when they use AI.

Using AI to improve quality control in manufacturing has several benefits. AI can find defects more accurately than humans, reducing the need for manual inspections and ensuring that every product meets high standards. This results in fewer mistakes, better products, and happier customers.

AI can improve the supply chain by guessing how much of a product will be needed. It also keeps track of how much stock is available. It can identify any issues before they become a big problem. This helps things run smoothly and saves money.

AI is used in robots to help them work well with people. These robots, called "cobots," can do things like putting things together and welding accurately. AI helps them adjust to different jobs and work safely with people, which makes manufacturing more efficient.

AI helps us save energy by figuring out how we use it and finding better ways. It also helps us use less energy and find where to save money. This means we spend less on energy and can make things more eco-friendly.

Industries such as car manufacturing, electronics, airplane production, and everyday items benefit the most from AI in their factories. AI helps them work better, spend less money, and make better products. It is like having a super-intelligent helper that allows these industries to keep up with the competition and make excellent stuff that customers want.

Examples of AI-driven innovations in manufacturing include AI-powered visual inspection systems that check for defects, predictive maintenance tools that forecast equipment failures before they happen, and generative design software that creates optimized product designs. These innovations help improve efficiency, reduce errors, and enhance product quality.

AI can improve things by looking at data and finding where things are not working efficiently. Then, it suggests how to do things differently to make them smoother and more productive. This helps companies do better and spend less money when making things.