What Is The Impact of AI On The Manufacturing Industry?

Artificial Intelligence (AI) is impacting how things are made, and it’s happening right now. One industry that’s benefiting a lot from AI is manufacturing. Studies suggest that AI could contribute up to $15.7 trillion to the manufacturing industry by 2025. In 2019, the global market for AI in manufacturing was valued at $1.82 billion, and it’s expected to reach $9.89 billion by 2027, growing at a rate of 24.2% per year.

Manufacturers are getting the benefits of AI in various ways. They’re cutting production time, saving money, and working more efficiently. AI is also helping to improve the management of supply chains, cutting down on manual tasks by saving businesses around 6,500 hours each year. For example, the Danone Group enhanced their demand forecasting by 20% and reduced the workload for planners by 50% using AI.

A majority of industrial leaders—61%—believe that AI can boost productivity the most, and 95% think that AI will make their companies run more smoothly. AI is transforming the manufacturing industry. In this blog, we’ll dig into how AI drives these changes, the benefits it offers, the latest advancements, and future trends in the manufacturing industry.

What is AI in the Manufacturing Industry?

Using Artificial Intelligence (AI) in the manufacturing industry means using innovative technology to help factories run better and more efficiently. This involves using advanced computer programs and machines to learn from data and make decisions. AI improves how things are made by adjusting machines to run at their best speeds and settings, which makes production faster and reduces waste.

One big advantage of AI in manufacturing is predictive maintenance. This means that AI can predict when something might go wrong with the machines before it happens. This helps prevent unexpected downtime and keeps the production line running smoothly. AI systems are also great at spotting defects or mistakes in products. They can check each item for quality in real-time, which means fewer defective products get out to customers, saving money and maintaining customer satisfaction.

AI helps manage the supply chain more effectively by predicting product demand, managing inventory levels, and optimizing shipping routes. This ensures that the right products are in the right place at the right time, reducing delays and cutting costs. In the AI manufacturing industry, robots perform repetitive or dangerous tasks for humans. These robots, controlled by AI, can work 24/7 without getting tired, increasing productivity and keeping workers safe.

Overall, AI in manufacturing uses data to make intelligent decisions, finding patterns and trends that humans might miss. This helps manufacturers make better decisions about everything from production schedules to maintenance needs. By leveraging AI, companies can make their operations more efficient, reduce costs, and produce higher-quality products, truly transforming the manufacturing industry and making it more competitive and innovative.

Discover the Power of AI in Manufacturing

Learn how AI can revolutionize your manufacturing operations. Our team is

ready to help you find the right AI solutions to increase efficiency,

reduce costs, and improve product quality.

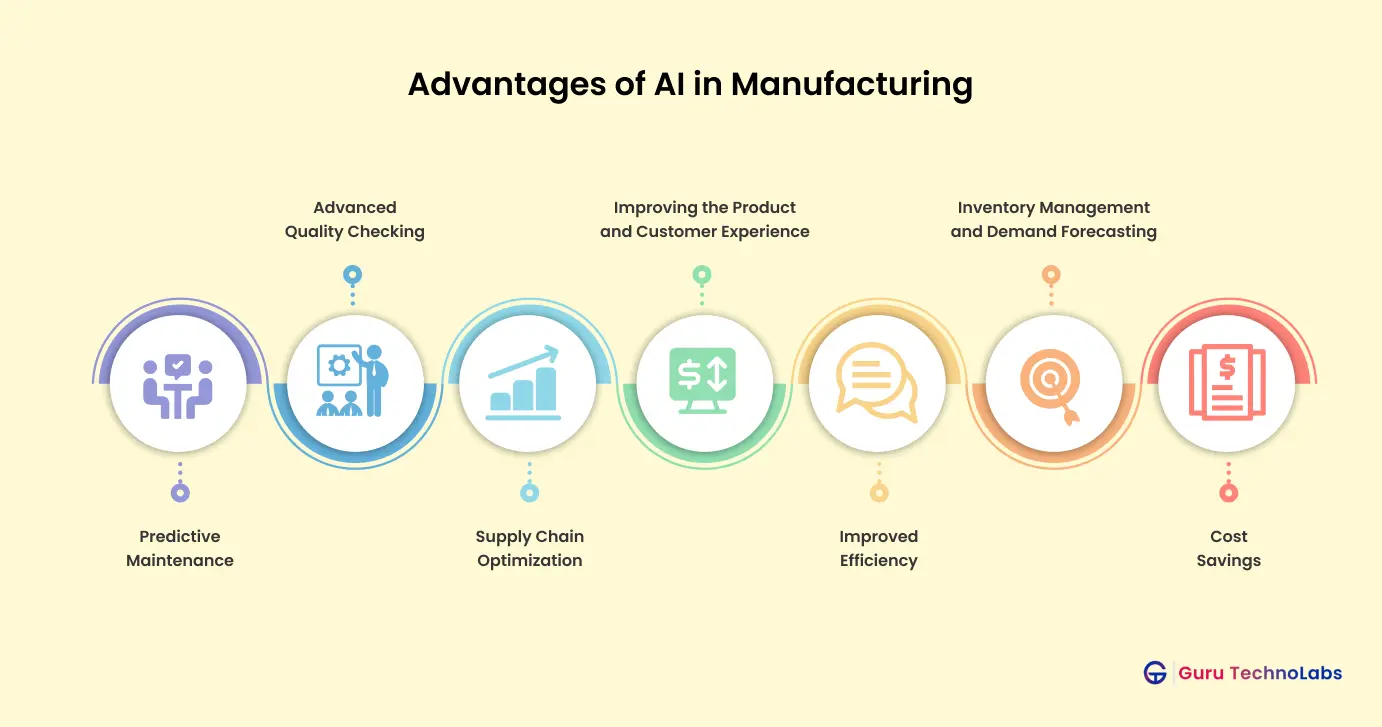

Benefits of AI in the Manufacturing Industry

Artificial Intelligence is changing how things are made in factories. It’s bringing many good things that help make things faster, better, and more efficient. When companies use AI, they can improve their factories and keep up with other companies in a constantly changing market. Here are some essential ways that AI benefits in manufacturing:

1. Predictive Maintenance: AI can look at data from machines and figure out when they might break. This helps companies fix problems before they cause the machines to stop working. As a result, unexpected downtime is reduced, and production keeps going smoothly.

2. Advanced Quality Checking: AI technology can find mistakes and issues as they happen. This helps ensure that our products are better quality and create less waste, making customers happier and decreasing the number of returns.

3. Supply Chain Optimization: AI can help make supply chains work better. It looks at how things move from the factory to the customer and determines how to make it faster and cheaper. This means stuff gets to where it needs to go on time, and it saves money.

4. Improved Efficiency: AI-driven automation helps with repetitive tasks so people can work on more exciting and creative jobs. This makes work faster and more efficient.

5. Improving the Product and Customer Experience: AI can help us understand what customers like and how healthy products work. This helps companies make better products that satisfy customers and improve their experience.

6. Inventory Management and Demand Forecasting: AI can predict how much of a product will be needed and help keep track of how much of that product is available. This can help companies ensure they have just the right amount of stock, reducing unnecessary production and preventing shortages.

7. Cost Savings: By using AI to automate tasks and predict when maintenance is needed, companies can save a lot of money. This means they can use that money for other important business-related things.

In short, AI helps factories work better. It makes things faster, more reliable, and cheaper. It also makes products better and makes customers happier. This allows companies to do well in a challenging market.

Advancements in AI for Manufacturing

AI technology has led to many new ideas in manufacturing. Here are some important ways AI is making a difference in manufacturing:

1. Industrial IoT Integration: AI combined with the Internet of Things (IoT) allows real-time monitoring and data collection from connected devices. This means that machines and sensors can communicate with each other and provide valuable information. Manufacturers can use this data to make better decisions, optimize production processes, and improve efficiency. This integration is a clear example of how AI in the manufacturing industry is revolutionizing operations.

2. Collaborative Robots (Cobots): Cobots, short for Collaborative Robots, are designed to work with people to make work easier and safer. Unlike regular robots, cobots can handle tasks that are repetitive or dangerous. This means that human workers can concentrate on more interesting and creative jobs, making the work environment safer and more efficient. Cobots are changing how we work in manufacturing thanks to their ability to work alongside people.

3. AI-Driven Analytics: Smart computer analysis helps companies in the manufacturing industry understand their business better. By looking through lots of information, AI can spot regular happenings and tendencies that help companies improve and develop new ideas. This means they can find new ways to improve their products, spend less money, and make their work more organized. AI’s job in the manufacturing industry is important for improving continually.

4. Smart Manufacturing: AI helps create intelligent factories where machines, systems, and people work together smoothly. In these smart factories, AI ensures that production runs well and efficiently. This means more things get made, better quality, and we can respond faster to what people want to buy. Smart manufacturing shows how much of a difference AI can make in making stuff.

The way AI is being used in manufacturing is changing things. It’s making manufacturing work better and safer, and it’s also making it more creative. When manufacturers use AI in their work, they can do things better than their competitors and make their customers happy. AI is making a big difference in manufacturing, bringing in new ideas and ways of doing things at every step of making stuff.

How to Successfully Implement AI in Manufacturing?

Using AI in manufacturing needs careful planning and execution to work well. Here’s a detailed guide to help you get started:

1. Assess Needs and Goals: Start by figuring out how AI can help you. Look at ways to work faster, save money, or make better products. Set clear goals for what you want AI to do. Understanding how AI affects manufacturing can help you set realistic and helpful goals.

2. Data Collection and Management: Ensure you have good data collection and management systems. This is important for AI to work well. You need accurate and relevant data to teach AI. Managing data well will help you make the most of your AI projects.

3. Choose the Right AI Solutions: AI technologies are different. Different AI solutions work for other things. Choose AI technologies that fit your specific manufacturing needs and goals. For instance, generative AI can help design and develop products, while predictive maintenance AI is good for keeping equipment in good shape.

4. Training and Skill Development: Make sure to train your employees to learn how to use and take care of AI systems. This will help them make the most of AI and solve problems.

5. Pilot Testing: Start with small pilot projects to test AI applications before going all in. This way, you can see how AI works in your situation and make any needed changes. Pilot testing helps find any issues and makes moving on to bigger AI projects easier.

Using AI in the manufacturing industry can help improve your operations if you do it right. Determine what you need, handle your data well, pick the best AI tools, train your employees, and test things out first. This will help you make the most of AI in manufacturing and increase productivity, efficiency, and innovation.

Ready to Transform Your Manufacturing Process with AI?

See how AI can make your manufacturing better. Our experts can help you

find the right AI solutions to work faster, save money,

and be more innovative.

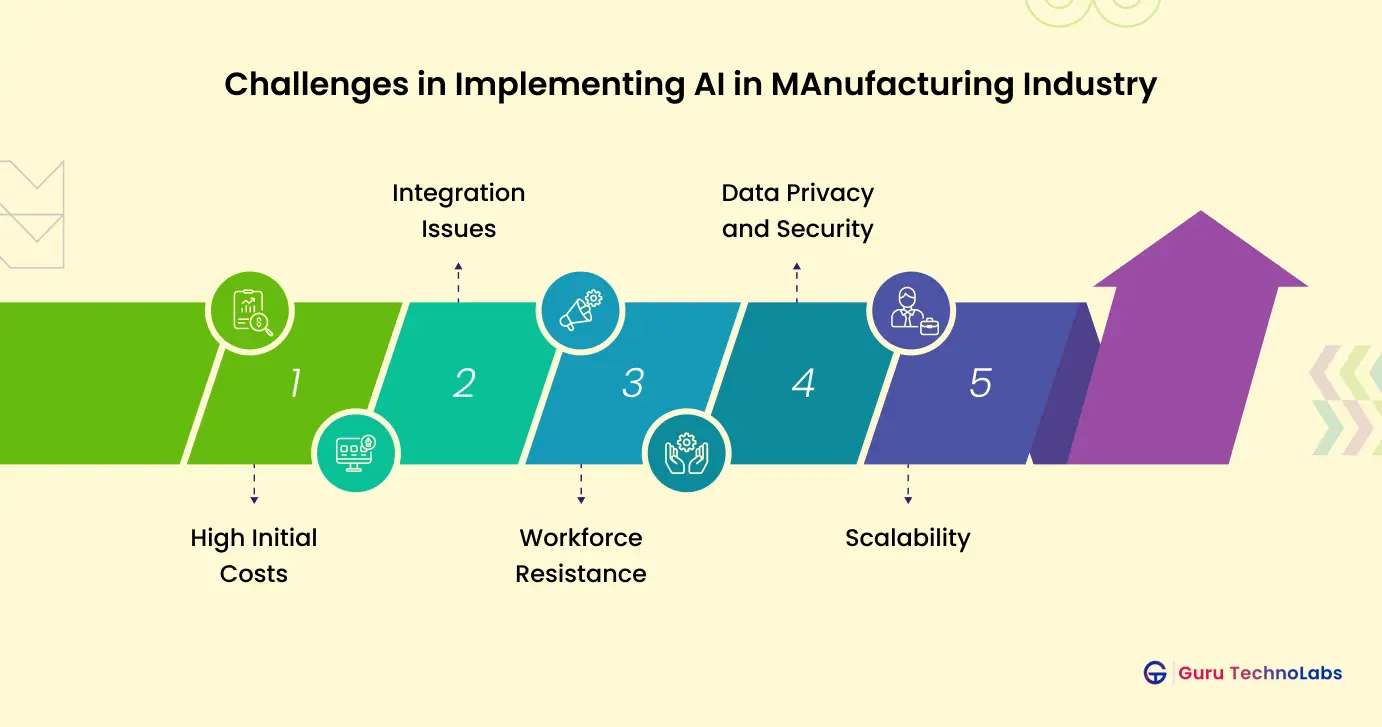

Challenges Faced in Implementing AI in Manufacturing

One of the benefits of using AI in manufacturing is that it can help make things more efficient. However, some problems can arise when companies try using AI. Here are a few of those problems:

1. High Initial Costs: The upfront expenses for AI technology and the necessary infrastructure can be high. This includes the costs of new equipment, software, and employee training. For many businesses, especially manufacturers, seeing the immediate benefits that justify these costs can be difficult.

2. Integration Issues: Integrating AI with current systems and processes can be tough and take time. Older equipment and outdated software might not work well with new AI technologies. Companies often have to update or change their current systems, which can be a big challenge.

3. Workforce Resistance: It can be scary for workers to think that new technology like AI might take over their jobs or make their skills outdated. Companies should talk to their employees about these concerns and help them adapt by providing training and support.

4. Data Privacy and Security: It’s important to ensure that data is kept private and secure when using AI. AI systems use a lot of data, some of which might be private. Companies need to put strong security measures in place to keep this data safe from hackers and people who shouldn’t have access to it.

5. Scalability: Making AI work in multiple factories can be challenging. When used everywhere, what goes well in a test might not be so great. Companies must plan and test AI carefully to ensure it works well everywhere.

Even though using AI in manufacturing has some challenges, the good things it can bring are big. If manufacturers work on these challenges early on, they can use AI to make their operations much better and more productive.

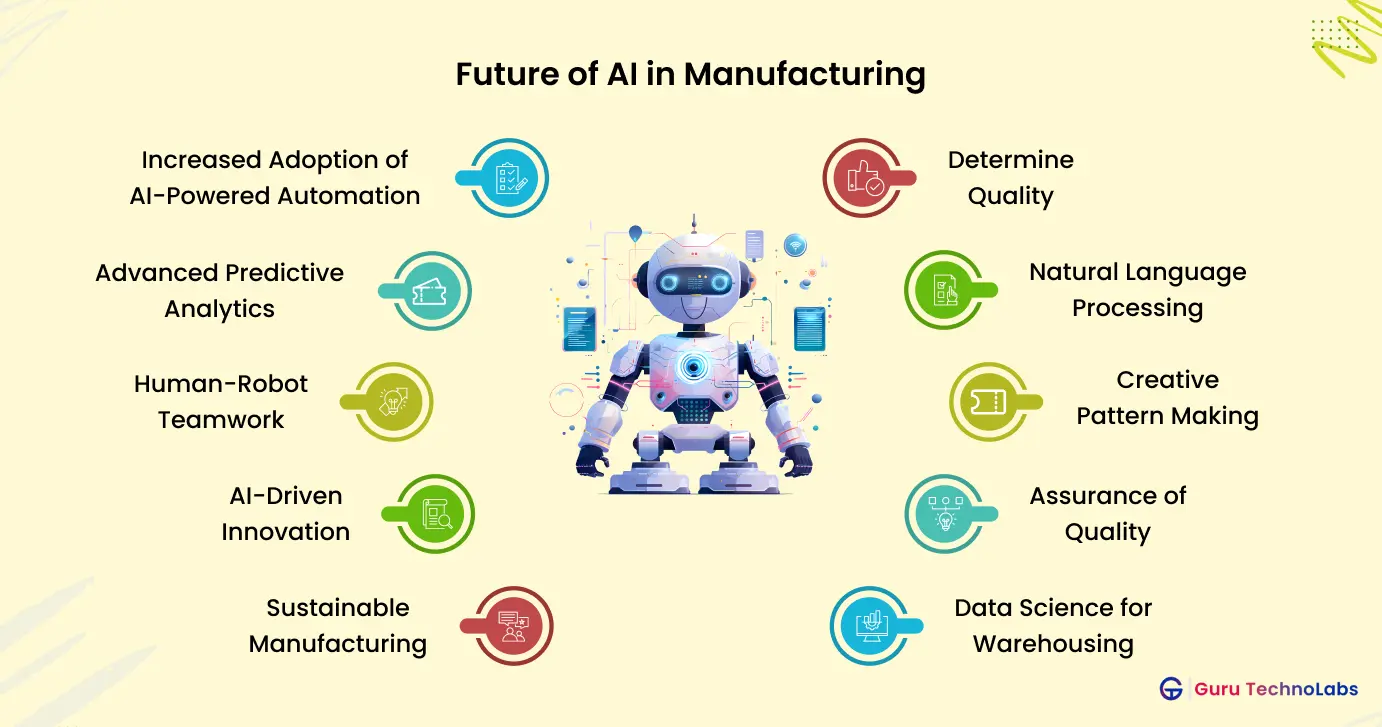

Future Trends of AI in Manufacturing

The future of artificial intelligence (AI) in manufacturing is inspiring, with many new trends that will completely change the industry. Here are some of the main trends that we can look forward to:

1. Increased Adoption of AI-Powered Automation: In the near future, more companies in the manufacturing industry will start using AI technology to automate their processes. This will help them become more productive and efficient. Robots and machines will take over tedious, repetitive tasks so human workers can focus on more exciting and creative jobs. As a result, manufacturing will become faster and produce more goods.

2. Advanced Predictive Analytics: AI is getting even better at predicting when machines might break down, helping companies save money by fixing things before they cause any problems. This also means that products will be checked more carefully during manufacturing so any issues can be fixed early on. This is one of the most impactful AI trends in the manufacturing industry.

3. Human-Robot Teamwork: Robots that work alongside humans, called cobots, will become more advanced. They can do dangerous or repetitive tasks, making work safer and more efficient. This teamwork will improve work and let humans focus on tasks requiring creative thinking and problem-solving skills.

4. AI-Driven Innovation: AI will change how we make things. It will help companies develop new and better products by using data to determine what customers want. This will make sure that companies stay ahead of their competition. The future of AI in manufacturing will see AI playing a crucial role in every stage of product development.

5. Sustainable Manufacturing: AI will make manufacturing more sustainable using better resources and less waste. AI can help companies make processes that use less energy, create less waste, and have less impact on the environment. Making manufacturing more sustainable will be very important as companies work to follow environmental rules and make products that are better for the environment.

6. Determine Quality: AI is being used more and more to check and guarantee the quality of products. It looks at data immediately and can find mistakes and differences when things are being made. This helps keep high standards and lower waste. Using AI like this in manufacturing will lead to more reliable product quality and fewer times when products have to be called back.

7. Natural Language Processing: The future of AI in manufacturing involves using Natural Language Processing (NLP) to help machines and humans communicate better. NLP allows machines to understand and respond to human commands more efficiently, which makes operations run more smoothly. This advancement will make it easier for people to interact with technology in manufacturing.

8. Creative Pattern Making: AI is being used to create and identify patterns in manufacturing processes, helping to come up with innovative product designs and making production more efficient. By recognizing trends and anomalies, AI helps optimize processes and develop new products. This creative use of AI is set to drive further innovation in the manufacturing industry.

9. Assurance of Quality: AI is revolutionizing the manufacturing industry by helping to ensure high product quality. It constantly monitors production data, quickly identifies and solves any problems, and maintains consistent quality standards. This is a key trend in the manufacturing industry and is essential for achieving excellence in production.

10. Data Science for Warehousing: The use of AI and data science is changing how warehouses work. They help manage inventory better, forecast demand, and make supply chains more efficient. AI analyzes large amounts of data, making warehouse operations smoother, cutting costs, and boosting overall efficiency. These changes will have a big impact on the manufacturing industry, making supply chains stronger and more adaptable. AI trends are shaping the future of manufacturing.

Conclusion

AI is making a big difference in the manufacturing industry. It is helping to make things run smoother, improve the quality of products, and come up with new ideas. Even though it’s not easy to bring in AI, the good things about it are much bigger than the bad. AI has a significant impact on manufacturing and is becoming increasingly important for the future of the industry.

As technology improves, we’ll see even more AI used in manufacturing. This will make production processes more innovative, more efficient, and better for the environment. Using AI will help manufacturers keep up with the competition and meet the market’s growing needs.

Frequently Asked Questions

AI in manufacturing refers to using intelligent computer programs and machine learning to improve production processes. This helps factories operate more efficiently, reduce waste, and create higher-quality products.

AI is making factories work better by doing tasks automatically. This helps workers focus on more important jobs. AI can also predict when machines need fixing so they don't suddenly stop working. It also helps track supplies and ensure things are made well. This makes factories run smoother and costs less.

To use AI effectively in manufacturing, start by figuring out where AI can be helpful. Then, make sure to gather and organize data smartly. Choose AI tools that are right for your needs and teach your employees how to use them. Finally, try the AI tools on a smaller scale before using them everywhere to ensure everything works well. Check out more use case of ai in manufacturing.

The benefits of AI in manufacturing are numerous. It helps by doing tasks automatically and making production faster. It also finds mistakes quickly, so the quality of the products is better. AI can predict when machines must be fixed so they work well and don't break. It also makes supply chains work better. Ultimately, using AI in manufacturing saves much money by reducing waste and lowering costs.

Using AI in manufacturing comes with several challenges. These include the high cost of getting started, problems integrating AI with current systems, employees being resistant to changes, worries about keeping data private, and difficulty scaling AI across different parts of a business.

Yes, AI is beneficial in manufacturing. It can look at data from machines and tell when they might break. This helps factories plan when to fix things before they break, which reduces how long things are not working and saves money on repairs. By dealing with possible problems before they happen, AI helps ensure that factories run smoothly and get more done.

AI can help ensure that products are made well by quickly finding mistakes and problems. This helps factories fix issues immediately and create better products with less waste.

AI and IoT working together means that factory machines and devices can talk to each other and share information immediately. This helps managers and workers make better decisions quickly using the latest data from all the connected devices.

Cobots, or collaborative robots, are made to work alongside people in factories. They can do tasks that are dull, risky, or need a lot of accuracy so that people can focus on more complex jobs. AI makes cobots even better by helping them learn and adjust to their surroundings. This makes them work more effectively and safer around people in factories.

The future of AI in manufacturing looks promising. With increased automation, advanced predictive analytics, enhanced human-robot collaboration, AI-driven innovation, and sustainable manufacturing practices shaping the industry, AI will transform factories' operations, making them more efficient, innovative, and environmentally friendly.